Why Choose this product?

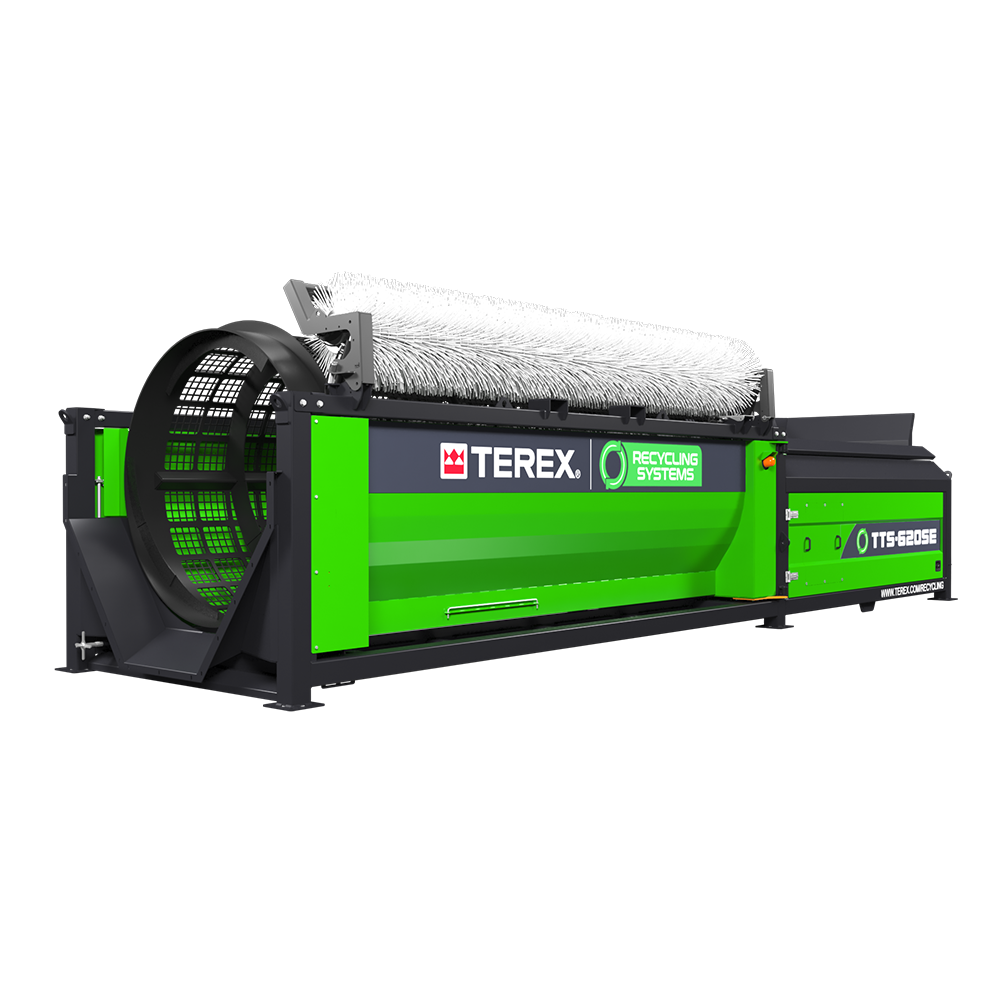

Terex Recycling Systems TTS-620SE Static Electric Trommel offers operators unparalleled versatility in applications, production rates and effortless serviceability. Specifically designed for screening compost/organics, biomass, soil, gravel and waste, it stands as an ideal choice for your needs.

The TTS-620SE benefits from an electric head driven feed conveyor to prevent the slippage associated with a tail drive configuration whilst under load. This ensures a consistent material feed onto the screening drum, enhancing screening efficiency and throughput. Due to this, you can enjoy heightened operational efficiency, improved screening quality, and reduced maintenance needs. The controlled material feed minimises wear and tear, extending equipment lifespan, while the user-friendly design adds operator convenience. With increased versatility and optimised performance, the TTS-620SE stands as a reliable solution for your diverse screening needs.

Supplied with a free-standing control panel, the intuitive user interface allows for easy set up and running. Simple controls allow for quick adjustments to the feeder and drum speeds to tailor the trommel screen to suit your application. With the optional advanced control panel with intelligent feed system, the operator can continually adjust the feeder speed to optimise screening rates. Special emphasis has been placed on reducing the change-out time for the screening drum. Large access doors and a retractable feeder cassette ensure the changing of a drum can be done quickly and efficiently ensuring minimal downtime to your operation. The machine has also been designed to accept several other manufacturers screening drums.

Exceptional levels of service access catapults the TTS-620SE into a league of its own. The full-length drum doors on both sides of the trommel drum offer unobstructed access for maintenance and cleaning. These, alongside the feeder side access doors and a slide out feeder cassette, ensure the TTS-620SE provides easy access for operation and routine maintenance.

Terex Recycling Systems TTS-620SE Static Electric Trommel offers operators unparalleled versatility in applications, production rates and effortless serviceability. Specifically designed for screening compost/organics, biomass, soil, gravel and waste, it stands as an ideal choice for your needs.

The TTS-620SE benefits from an electric head driven feed conveyor to prevent the slippage associated with a tail drive configuration whilst under load. This ensures a consistent material feed onto the screening drum, enhancing screening efficiency and throughput. Due to this, you can enjoy heightened operational efficiency, improved screening quality, and reduced maintenance needs. The controlled material feed minimises wear and tear, extending equipment lifespan, while the user-friendly design adds operator convenience. With increased versatility and optimised performance, the TTS-620SE stands as a reliable solution for your diverse screening needs.

Supplied with a free-standing control panel, the intuitive user interface allows for easy set up and running. Simple controls allow for quick adjustments to the feeder and drum speeds to tailor the trommel screen to suit your application. With the optional advanced control panel with intelligent feed system, the operator can continually adjust the feeder speed to optimise screening rates. Special emphasis has been placed on reducing the change-out time for the screening drum. Large access doors and a retractable feeder cassette ensure the changing of a drum can be done quickly and efficiently ensuring minimal downtime to your operation. The machine has also been designed to accept several other manufacturers screening drums.

Exceptional levels of service access catapults the TTS-620SE into a league of its own. The full-length drum doors on both sides of the trommel drum offer unobstructed access for maintenance and cleaning. These, alongside the feeder side access doors and a slide out feeder cassette, ensure the TTS-620SE provides easy access for operation and routine maintenance.